Efficient and sustainable

Service life is significantly increased

More than half of the 116 tunnels on the RhB network will have to be refurbished due to their age in the coming decades. Rhaetian Railway has developed a new, standardised refurbishment procedure for this purpose: "standard tunnel construction". This process ensures clear procedures, lower costs and enables refurbishment during ongoing railway operations. It also increases safety and extends the service life of the tunnels from what was 30 to 50 years to 70 to 100 years.

The new method involves completely replacing the tunnel walls and no longer "just" restoring them. To this end, the track is lowered, the tunnel cross-section enlarged, a new drainage system created, precast concrete elements used as walls and the portals rebuilt. This means that the tunnel can be refurbished while they are in operation.

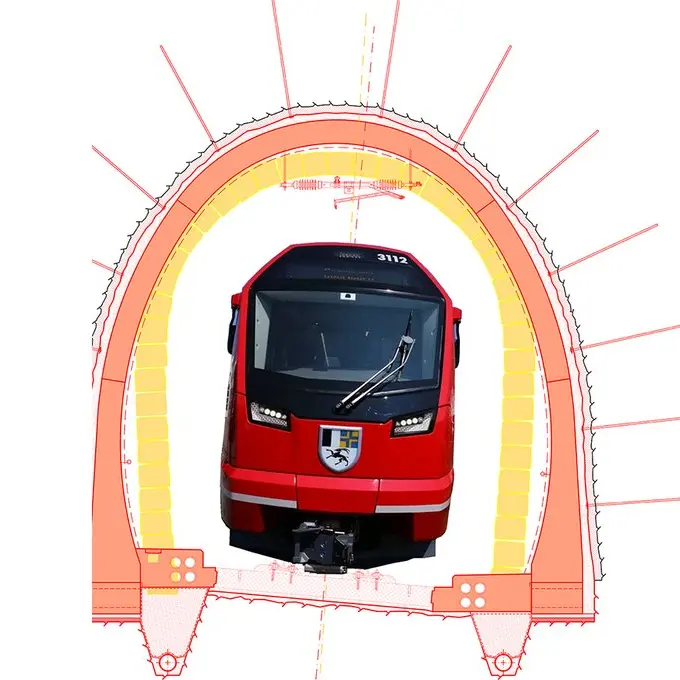

The picture shows an old (yellow) and new (red) tunnel corss-section with a fixed track and a Capricorn railcar.

Successful implementation

Refurbishment on the Glatscheras Tunnel 2014 - 2017

The "standard tunnel construction" method was used for the first time in the refurbishment of the approximately 108-year-old and 334-metre-long Glatscheras Tunnel below Bergün. The track was lowered by 52 centimetres for the refurbishment of the tunnel. This was followed by the enlargement of the tunnel cross-section using blasting and the precast concrete elements were installed from a freight wagon.

RhB played a pioneering role with this project and sparked the interest of other railway companies. Other tunnels such as the Sasslatsch Tunnel (Susch - Lavin) and the Mistail Tunnel (Solis - Tiefencastel) were later refurbished using the same construction method.

The picture shows the placement of concrete elements in the Glatscheras Tunnel using a specially developed positioning device.

Further developments

Fixed track for the first time

The Bergünerstein Tunnel was the first tunnel to be fitted with a fixed track: the tracks were no longer mounted on sleepers and laid in gravel; instead, a concrete slab construction with pre-assembled support points was used to secure the tracks.

RhB developed this variant further together with specialist planners for the Toua Tunnel (Muot - Preda) and Brail Tunnel || (Cinuos-che-Brail - Carolina) and standardised it so that the track conversion can take place in a complete closure lasting just a few days. In addition to increasing productivity, it can also be ensured that no speed restrictions need to be put in place when passing through the construction site, thus preventing any disruption to the timetable.

The use of prefabricated elements had to be dispensed with for sections with an incline of more than 5% in order to ensure adequate construction site supply. The tunnels in question will be fitted with a conventional inner shell made of shotcrete. This construction method was used for the first time at Val Varuna Tunnel | (Cavaglia - Cadera) on the Bernina Line.

Outlook...

Rhaetian Railway will continuously adapt the "standard tunnel construction" method to current building materials and construction methods in line with requirements. The experience and flexibility gained in the pilot projects will make it possible to work on several projects at the same time on the Albula, Engadin, Arosa and Bernina Lines in future.